Biocon has made significant investments in building commercial scale, globally compliant manufacturing infrastructure across diverse technology platforms. Our state-of-the-art manufacturing facilities – both microbial and mammalian – are designed to conform to the most stringent cGMP guidelines, comply with international regulatory standards and meet client requirements worldwide. Our products are manufactured at scale for both developed and emerging markets in Bengaluru (India) and Johor (Malaysia).

Our investments in building global scale have led us to rank among the world’s Top 15 biomanufacturing companies. We are among the leading insulin producers worldwide and have one of the largest antibodies manufacturing capacities in South Asia.

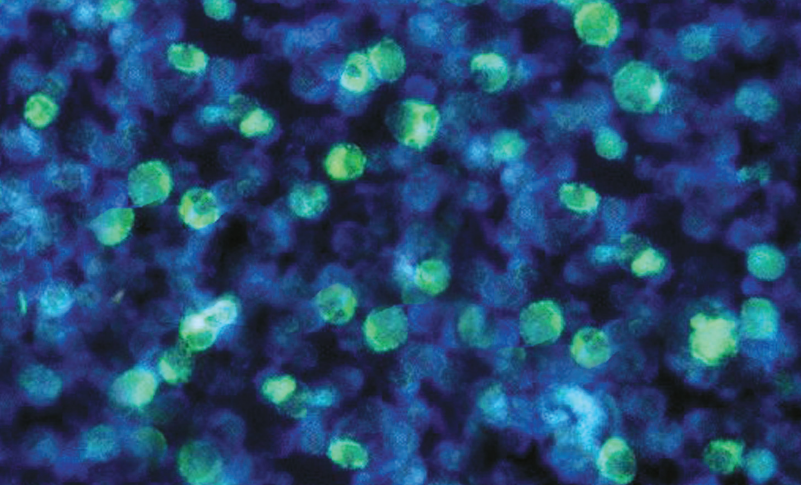

The breadth and scale of Biocon’s manufacturing technologies encompass large-scale microbial fermentation, chemical synthesis, mammalian cell culture, protein & antibody purification, aseptic formulation and fill-finish. Our manufacturing facilities are designed to stringent cGMP standards and are supported by state-of-the-art process development and quality control laboratories and an efficient service infrastructure.

Our capabilities and technologies have helped us emerge as an end-to-end player with a strong pipeline of approved biosimilars.

Our investment strategy is to build capacity in a modular manner, in line with our projection of market opportunity.